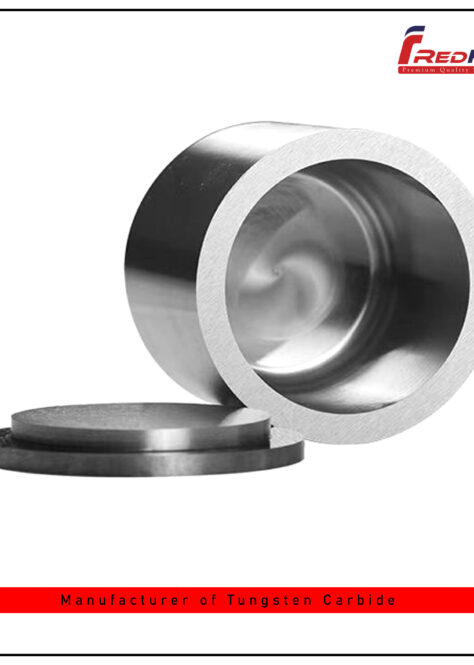

Rollers & Pulley

Tungsten Carbide Guide Rollers, also known as carbide rolls, rolling rings, guide rolls, can be customized according to needs.

Advantages:

Cemented Tungsten carbide is successful composite engineering materials with a unique combination of strength, hardness, and toughness that satisfies the most demanding wear applications.

We have developed our own grade for wear application products and achieving resistance to wear, deformation, fracture, corrosion, and oxidation.

Application:

- Descaling rolls are used for the mechanical descaling of entry rod in reduction mills for cleaning purpose.

- Rolls for wire ribbing.

- Hot Rolling Cemented carbide roll rings for rolling concrete reinforcement steel bars.

- High Speed Roll Rings for Rolling Ribbed Steel Bars.

- Roll rings with grooves is widely used hot roll mills to produce steel rod, wire, rebar.

- Wire guide rolls, used for wire guide in wire mesh industry.

- Straightening roller are used for metal wire straightening purpose.

- Straightening roller could provide uniform bending of wire or rod material to change its shape and possible other characteristics for use in subsequent processing.

- Descaling roller are used for metal wire cleaning purpose.

- Wire guide rolls and rollers, used for wire guide.

- Cold forming rollers, used to produce smooth or ribbed wire for the construction field.

- RO/RT/CA rollers, used to produce smooth or ribbed wire for the construction field.

- Profiling rollers, also called Ribbing rollers, used to produce ribbed wire for the construction field.

- Rolls for wire ribbing.

- Cold rollers are used for wire mesh industry.

- Can be used to manufacture drilling tools, mining tools, measuring tools, cylinder liners, precision bearings, nozzles, and many parts and tools in harsh environments.